FORKLIFT PREVENTATIVE MAINTENANCE

The Importance of Forklift Preventative Maintenance

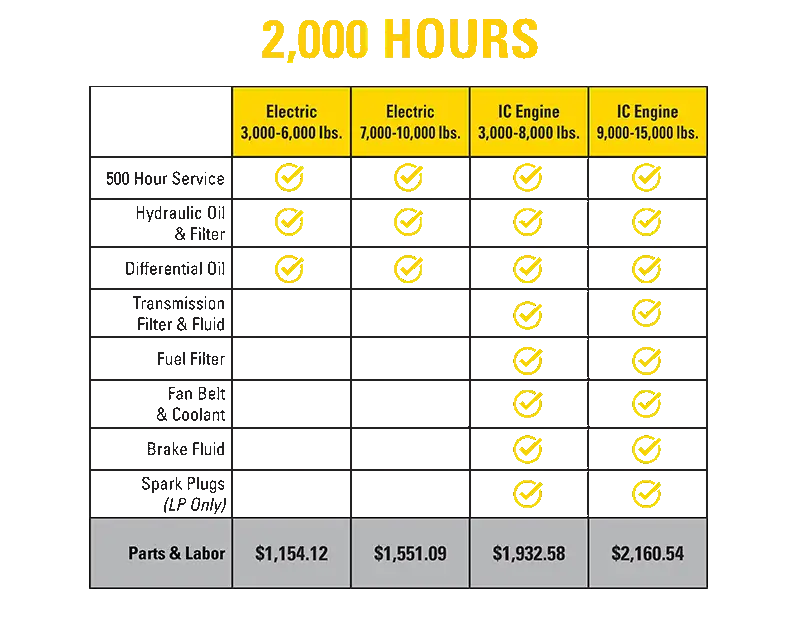

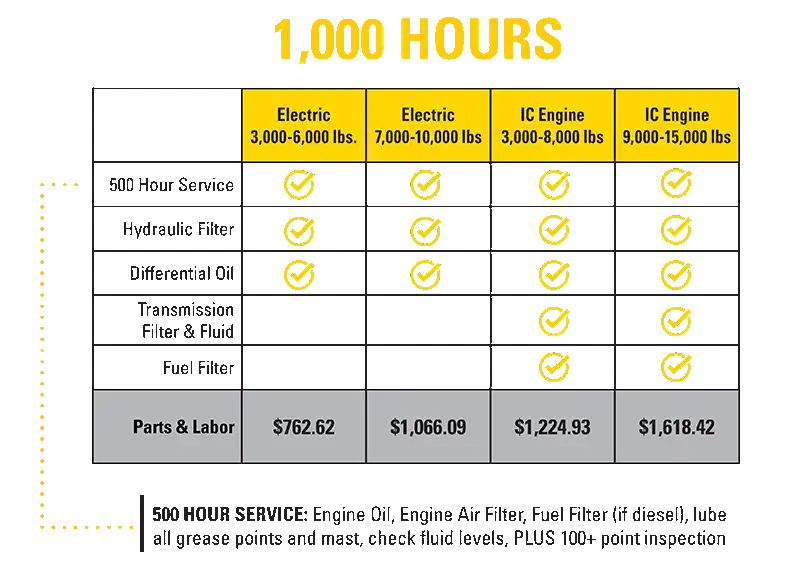

While forklifts are built to last, certain parts and components are prone to wear and tear due to constant use. To protect your forklift and your investment, forklift preventative maintenance is essential. Regular maintenance can help ensure optimal performance while reducing costly emergency repairs. Consistent care ensures your forklifts are easier to maneuver and makes your warehouse operations more efficient. Our forklift preventative maintenance plan is recommended every 250 hours of run time. We run forklifts through a 100+ point inspection and create maintenance schedules designed to keep your machines running smoothly while catering to their use time. These plans result in less downtown, longer equipment life, and a better trade-in value on your next forklift purchase.

What Are the Benefits of Forklift Preventative Maintenance?

You may understand the importance of forklifts to your business and how they need maintenance and servicing to keep them running efficiently. It's possible you may still need to consider how forklift preventative maintenance can benefit your business or how it helps you avoid substantial risk. Routine preventative maintenance can help protect the operator's life in case of an accident or mechanical failure. It also helps avoid unexpected part failures, resulting in ordering expeditated replacement parts and incurring additional costs on overtime labor or a rental forklift until your fleet is operational again. Our forklift preventative maintenance plans help avoid hidden fees such as employee idle times, the premium cost of ordering parts, reduced efficiency, and more. Preventive maintenance is essential, and if you have any questions, contact us. Our representatives are standing by to help.